The all-in-one machine for stripping and crimping tubular insulated terminals is specially designed for crimping bulk tubular insulated terminals. The terminals can be poured directly into the built-in miniature vibrating plate of the machine, and the terminals will be automatically sent to the crimping position. The wire end does not need to be pre-stripped. The operator only needs to put the wire end into the working position, and the machine can automatically complete a series of actions such as stripping, twisting the copper wire, penetrating the terminal, and crimping. The phenomenon of wire overturning, the stripping and crimping integration reduces the process flow and can effectively save labor.

One machine can crimp terminals of different sizes, just change the corresponding jigs. Color touch screen operation interface, parameter setting is intuitive and easy to understand, parameters such as thread cutting depth, stripping length, twisting force can be directly set in the program. This machine has a program memory function, which can save the stripping and crimping parameters of different products in the program in advance, and can call out the corresponding parameters with one key when switching wires or terminals.

Applicable wire: 0.25mm2, 0.5mm2, 0.75mm2, 1.0mm2, 1.5mm2, 2.5mm2, 4.0mm2

Applicable terminals: tubular insulated terminals (models that can customize aviation terminals)

Stripping length: 0~12mm

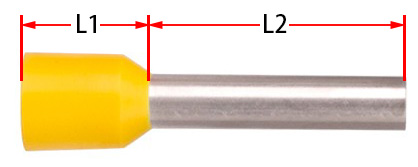

Terminal size: L1≤7.5mm, L2≤12mm

The shortest wire length: 40mm

Crimp shape: quadrilateral

Production efficiency: 1000~1200 pieces/hour

Working voltage: 220V 50Hz

Rated power: 500W

Air pressure requirement: 0.5~0.8Mpa

Net weight: 68kg

Dimensions: 430*505*425mm

| KS-T882T | KS-T882MT |

| No stress monitoring | With pressure monitoring |

Note:

The above specifications are for reference only. In the case of extremely hard, tough wires, processing may not be possible even within the cross section range. In case of doubt, KINGSING will be happy to provide processing samples of your wires.

Conforms to the relevant CE directives on machine safety and electromagnetic compatibility.

English

English